Cold Formed Steel Buildings

Cold-formed steel boasts exceptional strength, making it a viable option for constructing robust, long-lasting buildings. A cold-formed steel building (or CFSB), is a type of construction method that utilizes steel sheets or strips that are formed at room temperature to create various structural components. These components can include studs, joists, purlins, and other framing elements. Cold-formed steel is distinguished from hot-rolled steel, which is shaped at higher temperatures.

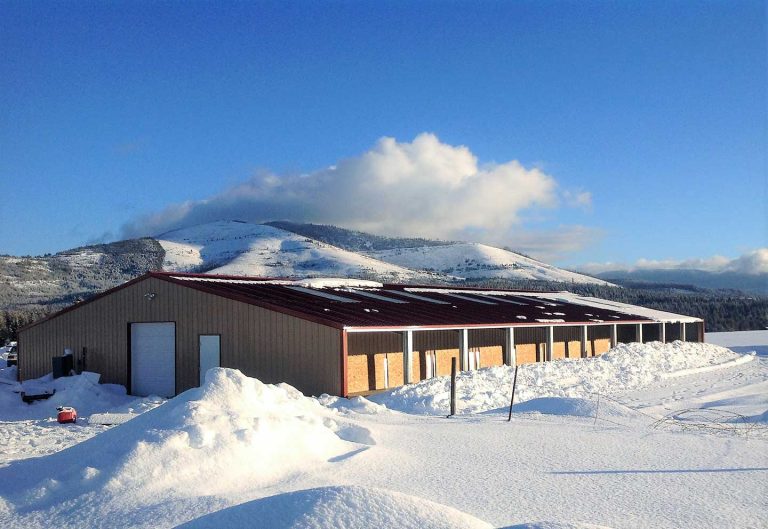

Cold-formed steel buildings offer a range of benefits, making them a popular choice in modern construction. They are used for a variety of purposes, from residential housing to commercial and industrial facilities. They have become an extremely popular option for customers looking to build Barn-dominiums!

In the realm of modern construction, innovation and sustainability have become paramount. Cold-formed steel buildings, are a product of this evolution and stand as a testament to the engineering prowess of the 21st century. These structures offer a variety of advantages, ranging from cost-effectiveness to environmental sustainability.

THEY CAN BE USED FOR:

- Commercial Buildings

- Industrial Buildings

- BARN-dominiums

- Small and Large Barns

- Home Workshops

- Residential Garages

...AND MUCH MORE

Traditional Red Iron Buildings

Traditional metal buildings consist of red iron frames and red iron substructural members. The frames are fabricated and welded together in a time and labor-consuming process.

Cold Formed Steel Buildings

Cold Formed buildings are constructed entirely with roll-formed components, eliminating the need to fabricate and weld frames. The end-result is lower lead times!

Cold Formed Steel Building Advantages

(click on the check-marks to learn more)

Shorter Lead Times

Quicker Installation

20-25% Less Concrete

Drill-in Anchors

Precise Components

A Cleaner Appearance

SHORTER LEAD TIMES

Measured in Weeks…Not Months!

Conventional metal buildings are notorious for long lead times that stretch into several months due to the fabrication process. Cold Formed Steel Buildings are constructed entirely with roll-formed components, which are more efficient to ship and eliminate the need to pre-fabricate and weld frames in a plant. The end-result is lower lead times!

QUICKER INSTALLATION

Start Using Your Building Sooner!

For Customers AND Contractors…time is money! Cold Formed Steel Buildings have precisely manufactured components that assemble easily on site without the need for welding. Installation crews can complete jobs quickly compared to same-sized buildings made from red iron. That means YOUR building is up and ready for use MUCH faster!

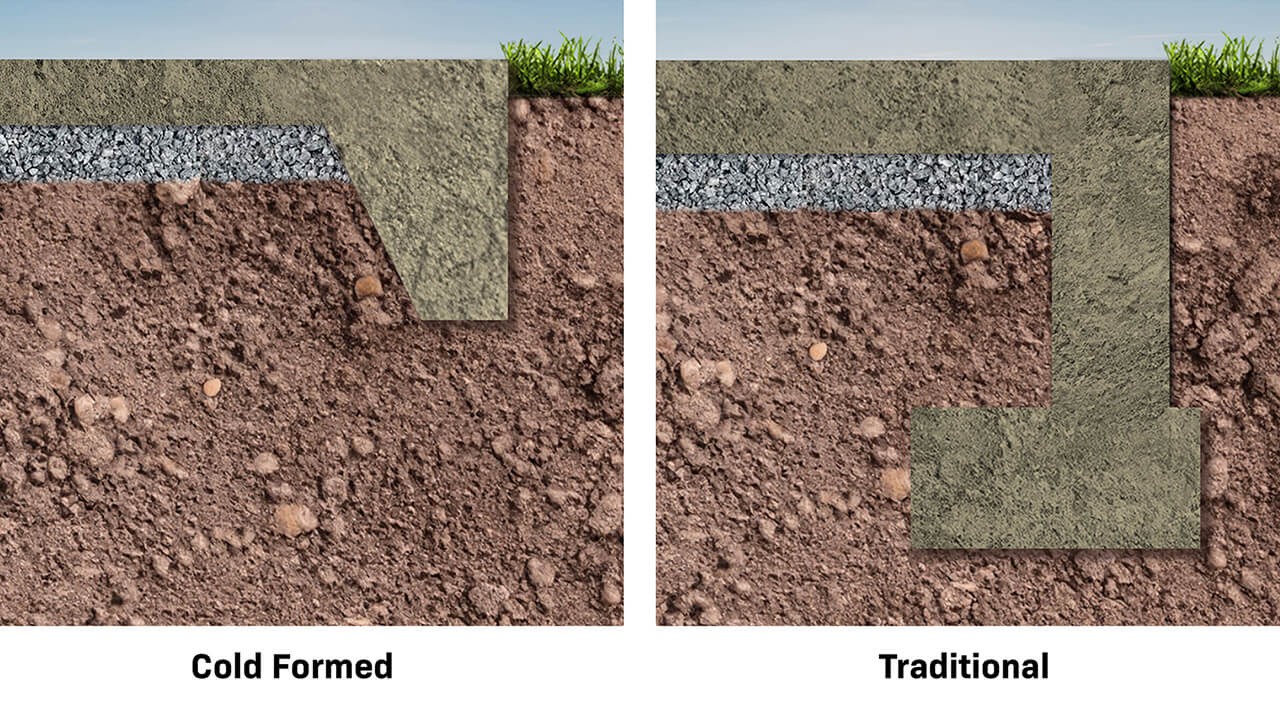

20-25% LESS CONCRETE

Lower Cost Building Foundation!

Cold Formed Steel Buildings spread the loads over multiple frame lines, resulting in smaller loads at each column. Compared to other structures, concrete foundations for Cold Formed Steel Buildings can be simpler and are often accomplished with a single pour. This results in a more efficient foundation design in both labor and material, which saves money.

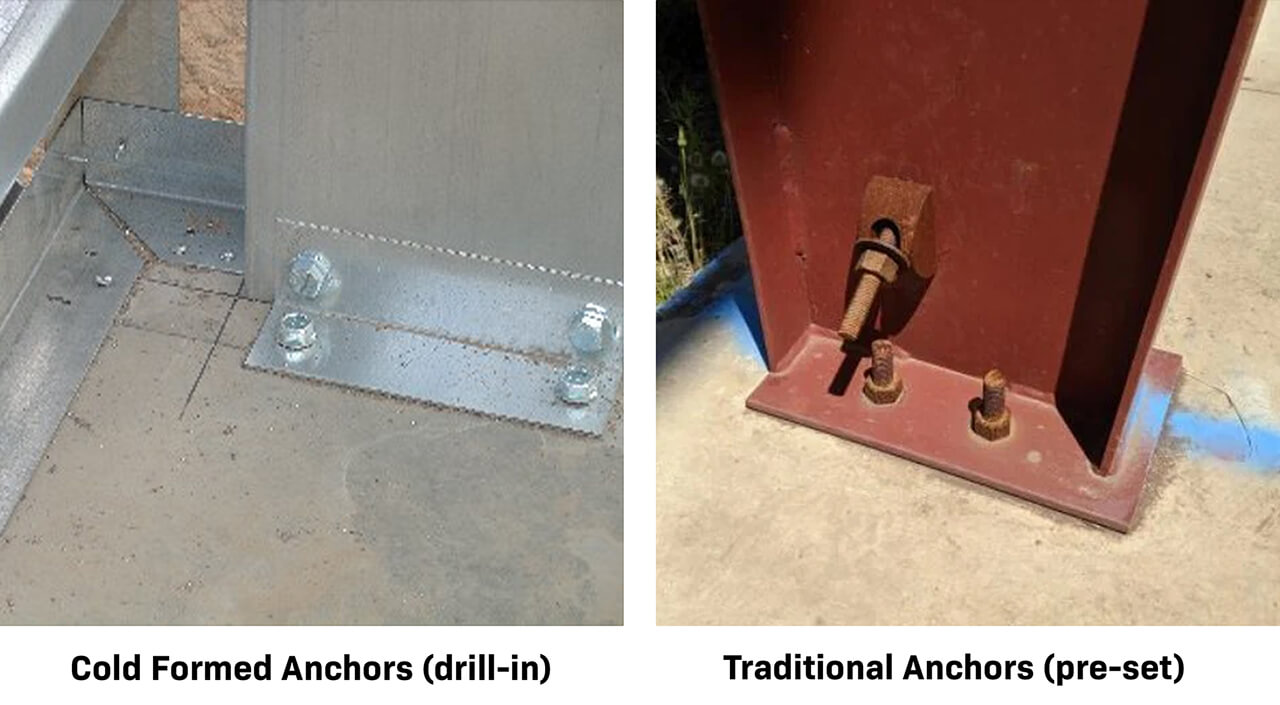

DRILL-IN ANCHORS

NO Need For Pre-set Anchor Bolts!

PRECISE COMPONENTS

Tighter Tolerances = Easier Assembly!

A CLEANER APPEARANCE

Ideal for Building Barn-dominiums!